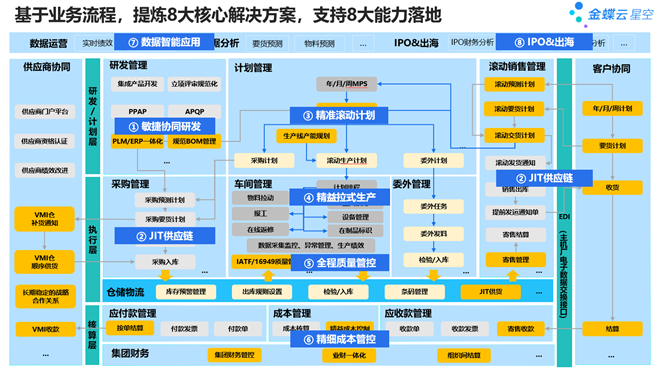

Kingdee auto parts industry solution

With the development of electrification, intelligence, modularization, and integration in the automotive industry, China’s automotive sector has experienced rapid growth. The business model of automotive parts companies has also undergone a qualitative change, gradually upgrading from a traditional technology-following approach to an independent innovation model; shifting from a focus on self-development to a greater emphasis on upstream and downstream collaborative development; transitioning from merely meeting delivery deadlines to placing more importance on agile responses to customer needs and quickly capturing market share; moving from traditional production completion based on delivery dates to a greater focus on building a lean system for optimal efficiency; and gradually expanding from domestic business competition to layouts outside the Chinese Mainland, enhancing global influence.

All these transformations and upgrades are driven by digital capacity. For over 30 years since its establishment, Kingdee has combined practical experience and digital products to provide eight core capacity builds for numerous automotive parts companies, assisting them in their renewal and upgrade.

1. Agile R&D capacity for collaborative R&D and quick conversion of research and production.

Through the PLM cloud, we provide APQP & PPAP research and development projects and quality management that meet industry requirements, as well as an integrated R&D system for overall and component-level collaborative development, rapid conversion from research to production, global impact assessment of changes, and supporting operations.

2. Quick response to customer orders and JIT supply chain capacity.

By building EDI, we can obtain real-time demands from Parent customers; through rolling sales, we connect with customers’ rolling forecast plans and rolling goods purchase plans, and the system generates a rolling delivery plan based on the demands, efficiently responding to customers’ goods purchase needs; and by using the VMI model (consignment and VMI rolling purchase) and supply-purchase collaboration, we establish a supply chain system that meets the MMOG/LE framework, achieving JIT collaboration across the upstream and downstream of the industry chain.

3. Efficient and precise rolling plan capacity

Through the configurable forecasting reduction module, accurately determine the demand, and through the rolling planning workstation, provide simulated and visualized production scheduling results based on demand, resources, and capacity, helping planners efficiently and accurately formulate work plans, and guiding the execution of procurement, production, and outsourcing operations.

4. Extremely efficient lean pull production capacity

Through the duplicate production module, production scheduling is carried out in the form of a planned Kanban to undertake the rolling plan pushed down by the system; in conjunction with the barcode cloud, it achieves refined warehouse operations; and through line-side warehouse management, it realizes pull-based delivery according to consumption progress; by using mobile reporting, mobile quality inspection, and mobile barcodes, operators can perform lean operations anytime and anywhere, collaborate efficiently, and create an agile manufacturing system. Synchronously provide project-based manufacturing and discrete manufacturing control modes, supporting various business manufacturing modes for automotive parts enterprises.

5. Meet the IATF 16949 Quality Management <x1>Capacity</x1>.

Through the Quality Cloud, it supports quality control characteristics in the automotive industry such as FMEA, 8D, SPC, APQP, and PPAP; through detailed quality inspection plans and quality document management, it provides rigorous physical quality control at all stages including incoming material inspection, first article inspection, process inspection, patrol inspection, finished product inspection, and outbound inspection; through supplier quality management and after-sales quality modules, it offers upstream raw material and finished product after-sales quality management; through a quality knowledge base and process control for continuous improvement, it achieves overall quality optimization and forward and backward traceability.

6. Fine cost control capacity

Through the Cost Pool, provide standardized cost data and asset application to achieve digital cost trend analysis; through multi-organization finance, realize accounting across multiple organizations, regions, and systems; through the financial intelligent closing platform and smart applications, achieve the association and automatic circulation of business financial documents, automatic recognition of payments and receipts, AR bad debt risk warning, etc.; through the full cost accounting system, provide detailed finished product analysis from different dimensions such as product, batch, workshop, and process, achieving pre-control, in-process control, and post-control to reduce costs and increase efficiency.

7. Data Analysis, Intelligent Operations Capacity

Through data intelligence cloud, external data acquisition and internal data comparison are achieved, enabling analysis of supply chain, production, quality, and more. It provides risk monitoring and early warning for supply chain, orders, and legal matters, as well as forecasts for intelligent sales, demand, smart procurement replenishment, and funding. Additionally, it offers dashboards for analysis of supply chain, production, quality, and finance, providing decision-making support for intelligent enterprise operations.

8. IPO and business overseas <x1>capacity</x1> <x2>extend</x2> <x3>competence</x3>

Through the IPO center, we provide intelligent assessments and IPO project management for companies before their IPO listing, helping them achieve a smooth IPO; through IPO thematic analysis, we offer various analyses on themes such as assets, liabilities, income, costs, internal control compliance, and transactions related to XX, meeting the needs of various application scenarios before and after the IPO; through GlobalEase, a multilingual system, multiple accounting standards and accounting systems, global electronic invoicing, and tax compliance capabilities, we strongly support auto parts companies going global in conjunction with the integrated three-network system.

The Kingdee automotive parts industry characteristic package comprehensively addresses industry pain points and meets industry demands.

The development and growth of the new generation of automotive parts enterprises cannot be separated from the support of digital capabilities. The Kingdee automotive parts industry characteristic package, through PLM Cloud, EDI, rolling sales management, rolling procurement management, rolling planning and workbench, duplicate production management, manufacturing cloud, quality cloud, barcode cloud, mobile production, project cloud, financial cloud, and other modules, creates a collaborative R&D, agile response, planned production, lean manufacturing, precise control, accurate accounting, and efficient collaboration automotive parts digital intelligent enterprise.

+853 2853 3813

+853 2853 3813