The transformation of the auto parts industry is imminent

Current Market Situation and Common Issues in the Auto Parts Industry

The auto parts industry has a history of over a hundred years, and many theories and works of modern management have originated from the automotive or auto parts-related industries. However, the current automotive parts industry is facing unprecedented challenges, both from external and internal environments.

On one hand, traditional car enterprises are experiencing a stark contrast; the traditional passenger car market is becoming saturated and the overall market is declining, while the development of new energy vehicles is thriving, leading to a transformation and reshaping of the automotive industry supply chain.

On the other hand, the supply and price of raw materials are experiencing severe fluctuations, facing the risk of supply interruption at any time. Auto parts companies, positioned in the middle of the supply chain, are being squeezed from both upstream and downstream enterprises. Moreover, as the older generation of entrepreneurs gradually ages, the new successors show insufficient interest in traditional <Manufacturing> and lack understanding and experience in the industry, resulting in a lack of innovation and vitality in the <Enterprise>. Under the combined influence of various factors, the transformation of the automotive parts industry is imminent.

Industry Challenges

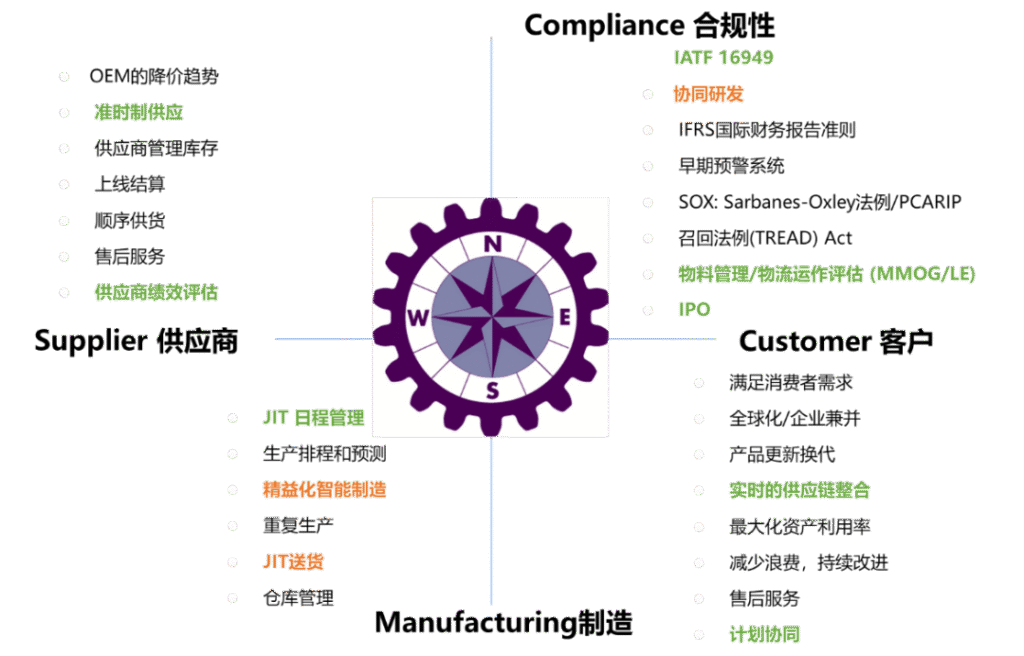

The traditional auto parts industry is mostly built around one or more host manufacturers, which often comes with a serious dependence on large customers. In the supply chain, host manufacturers undoubtedly hold absolute power. Although the positions of both supply and demand are quietly changing in the era of new energy, and even some suppliers with core technologies are in a dominant market position, for most auto parts companies, without the support of high-threshold core technologies, their market position remains passive, which brings a series of challenges.

01

The minute-level logout speed and EDI interface.

To respond to market changes, the OEM adopts an agile manufacturing strategy, and the Production Line generally operates with mixed production. Each vehicle has its own configuration List. Generally speaking, the vehicle Logout speed is about 47 JPH to 51 JPH, which translates to approximately 70 seconds, or a little over a minute. As the vehicle manufacturers’ production schedules change, the parts from both Level-1 and Level-2 supporting suppliers will also change accordingly, which can be described as a ripple effect. The demand for minute-level changes needs to be frequently communicated through the EDI interface to convey supply and demand information.

02

Billing Supply Mode

To align with the host manufacturers’ minute-level production response, supporting suppliers mostly provide goods in JIS (Just in Sequence) / JIT (Just In Time) delivery, with supply frequency reaching minute-level. First-Level suppliers with a close relationship will establish their own production workshops directly next to or across from the OEM, adjusting their assembly and Shipping Plan in real-time according to the OEM’s vehicle rollout schedule. Supporting suppliers must adopt a “broad to narrow” rolling planning model to cope with this.

03

VMI Consignment System and Zero Inventory

The host manufacturers adopt an agile production method, pursuing zero inventory in the production stage, but it is impossible to completely eliminate inventory for the entire supply chain, so the inventory of spare parts is left to the supporting suppliers. Suppliers need to establish a large number of VMI warehouses within or next to the host factory to respond to frequently changing customer requirements. Auto parts suppliers deliver the parts to the VMI warehouse in advance according to the schedule issued by the customer, and the host factory settles with the supplier based on the actual usage.

04

Product recall system and IATF16949

The product recall policy originated in the automotive industry, which greatly protects consumer rights. At the same time, the vehicle and auto parts manufacturers, as the producers, must have corresponding systems in place to ensure the quality process and trace the root of any quality issues. IATF16949 is a quality assurance system that sets specific requirements for various stages such as research and development, purchase, production, and sales. It is implemented throughout the OEMs and all levels of supporting suppliers, and the management of auto parts manufacturers must comply with the system requirements to become qualified suppliers.

05

The value of the Kingdee solution and points for management improvement.

Kingdee Cloud offers systematic digital transformation consulting services and product solutions for automotive parts industry clients, achieving digital transformation based on lean principles. Integrating core value-added systems such as PLM, MES, SRM, and ERP into a single database through the Starry Sky Cloud Platform, along with the integration of R&D and production, accelerates the quick launch of products to the market. By directly connecting ERP with MES equipment control through IT and OT, it more effectively improves quality and operational efficiency. Through the quick integration of the lean supply chain from supply to production, we flexibly meet the increasingly changing needs of the customer.

01

Solution

In the sales stage, the demand connection with the OEM is achieved through the EDI interface, and the demand is broken down into corresponding purchase requirements and production plans through the rolling schedule. In the production field, through multi-factory planning coordination, matching the supply and demand relationships of multiple factories, during the logistics delivery phase, coordinating the material delivery plan and the finished goods shipping plan to achieve precise satisfaction of customer demands.

02

VMI consignment and intelligent reconciliation solution

Kingdee Cloud provides perfect support for the VMI consignment system, accurately managing global VMI warehouse inventory levels, owner information, status information, and more. Combine the digital supply chain system to track the entire process of shipment, delivery, receipt, and quality inspection, providing accurate information for the final VMI reconciliation.

03

JIT digital supply chain solution

To cope with the complex and ever-changing collaborative forms in the automotive industry’s upstream and downstream, Kingdee Cloud not only provides EDI interfaces and VMI but also offers a complete vendor management solution to collaborate on vendor qualifications, shipments, barcodes, quality, and more. Through manufacturing and MES cloud, it helps enterprises build capabilities ranging from material readiness to material distribution, fine control of the production process, rapid handling of exceptions, process quality control, and full visibility and traceability of the entire status.

04

Integrated Solution for Production and Research

Kingdee Cloud PLM is the best platform for implementing the IPD R&D system, strongly supporting the comprehensive needs of the automotive parts industry for product, mold, process design, and quality planning. It also provides project management features for new products from concept design to prototyping, trial production, mass production, and the entire product lifecycle, integrating mainstream CAD/CAM software and EDA software in the market, and offering comprehensive digital support for materials, BOM, documentation, process routes, quality systems, and more.

05

End-to-End quality management scheme that complies with IATF16949.

The automotive parts industry requires the establishment of a complete quality management system and quality traceability management system that complies with IATF16949 in the field of quality management. Kingdee Cloud can provide a comprehensive full-chain quality management solution. During the process of introducing new products into mass production, users can manage the development and introduction process according to APQP requirements. In the R&D process, potential failure risks are eliminated through FMEA design to ensure product quality. Before mass production, quality records are achieved through the PPAP documentation package.

06

Lean Cost Management Solution

The auto parts industry faces significant market pressure. To ensure competitive pricing, it is essential to accurately control costs. Group enterprises require a group management system, while IPO or publicly listed companies must ensure internal control compliance. Kingdee Cloud provides integrated management and control of the entire industry chain’s finance and operations. Internally, it strengthens unified standards and management processes for the group and its subsidiaries. Externally, it enhances business collaboration for demand supply and accounts reconciliation between the main manufacturers and parts suppliers.

Closing Remarks

The auto parts industry has a long history and began its informatization efforts relatively early. However, objectively speaking, the early IT development was not very successful due to technical reasons and the management issues within the companies themselves. The new generation of ERP management platforms is no longer just a simple Purchase, Sales, and Inventory + financial accounting platform, but rather an integrated control platform that encompasses research, production, supply, sales, operations, finance, taxation, and invoicing, capable of fully meeting the digital transformation needs of enterprises. Through Kingdee Cloud, auto parts companies can navigate the digital era with ease.

+853 2853 3813

+853 2853 3813