How can manufacturing enterprises reduce design changes from the source

The hazards of design change

Manufacturing enterprises often experience design <x1>changes</x1>, and frequent design <x1>changes</x1> can cause many harms to the <x2>enterprise</x2>.

▪ Increase enterprise cost: Design changes will require more production resources, including repeated investments in manpower, materials, and financial resources. At the same time, design changes may also cause a large amount of material stagnation, leading to an increase in the company’s costs.

▪ Factors affecting product quality: Design changes may affect the quality of the product, requiring additional quality control and testing to ensure that the product quality meets the expected standards.

▪ Delayed Delivery Time: Design changes may impact the production schedule and supply chain management, leading to adjustments in the production line and issues such as material replacement, which in turn may cause delivery delays.

▪ Reduce production efficiency: Design changes may increase the rate of XXX Error and rework during the production process, thereby affecting production efficiency.

▪ Increased risk: Design changes may increase safety risks and environmental risks during the production process, requiring additional safety measures to ensure the safety and environmental protection of the production process.

Therefore, manufacturing enterprises need to fully consider these potential hazards when making design changes and take appropriate measures to reduce these risks.

Reason for the change in design.

There are many factors that trigger design changes, which we can simply divide into two main categories.

▪ External factors: If there are changes in customer demand, changes in the market environment, stock shortages caused by supply chain issues, changes in regulations and policies, etc., companies are forced to respond with design changes.

▪ Internal factors: If there is a design error, it is necessary to make a <x1>Correction</x1> to the design, <x2>Optimization</x2> of the design to improve product performance and quality, <x3>Optimization</x3> of <x4>Cost</x4> and the supply chain, and to identify product <x5>Defects</x5> during product validation or production use.

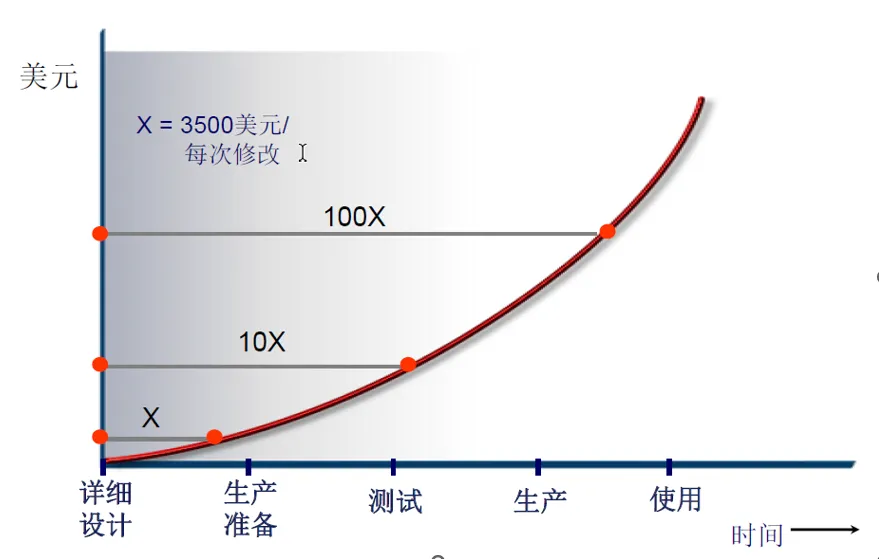

The losses caused by design changes are closely related to the timing of the design changes. Modifying the design during the research and development design phase can be completed with minimal time and cost, whereas design changes that occur during production or even the customer usage phase will incur heavy costs for the company.

The later the design change occurs, the greater the loss incurred.

Analyzing the reasons for design changes and the relationship between the losses caused by design changes and time, we found that optimizing the product development system can reduce the probability of design changes occurring and can Pre-delivery the occurrence of design changes as much as possible, which can effectively reduce the losses caused to the enterprise by design changes.

How can manufacturing enterprises reduce design changes from the source?

The research and development stage determines 70% of the product’s cost and quality, while the frequency of design changes is an important indicator of the maturity of product R&D management. Many design errors and information transmission mistakes that cause significant losses to enterprises can be avoided by establishing a sound R&D management system.

1

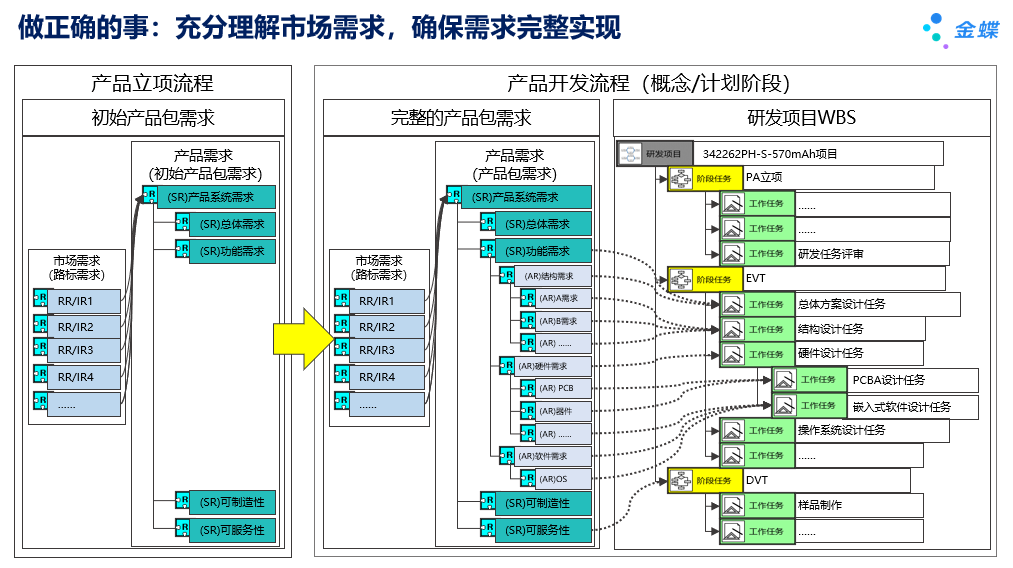

Strengthen Requirement Management

In many cases, our requirements come directly from the <Customer>, but sometimes, the <Customer> is not clear about what they actually want. If we cannot guide them to express their true thoughts, or if we do not fully understand the users’ needs and intentions, then the developed product may not be what the customer wants, and it may not meet the customer’s expectations. This can also lead to changes in requirements and even delays in product delivery.

Therefore, we need to establish a standardized <x1> requirement collection template and <x2> flow, digging into the true <x3> requirements behind the customer’s demands from the customer’s perspective, to improve the quality of <x4> analysis. It is also necessary to convert customer and market requirements into quantifiable, feature-based product requirements, and associate each requirement with R&D tasks to ensure that all requirements are met.

2

Strictly follow the research and development process.

The R&D flow contains the lessons learned from the enterprise’s R&D, which can reduce the impact of human factors on R&D quality. The consequence of poor R&D quality is the occurrence of new design changes. Many companies have research and development processes that are essentially a formality, believing that adhering to the requirements of the R&D process will hinder efficiency. However, the result is that some key process nodes are not strictly followed, leading to design errors that are not detected early. The future corrections for these errors will incur more time and financial costs.

3

Improve the effectiveness of technical reviews.

The research and development process requires corresponding technical reviews to be conducted during the stages of project initiation, program design, detailed design, design verification, and customer verification. To identify design issues during the technical review process, it is essential to establish and continuously update a detailed review criteria table, and to conduct the review strictly based on the requirements of the review criteria table. The technical review team should include representatives and experts from relevant departments such as Marketing, Purchasing, Manufacturing, and Service to identify any issues with the product solutions and designs as early as possible. For the errors identified during the review, a specific Person Responsible should be designated to resolve the issues on time according to the problem handling Flow.

4

Achieve product platforming, modularization, and standardization.

The result of product platformization, modularization, and standardization is to maximize the use of existing technologies and materials to develop new products, concentrate the research and development efforts of the Chinese Enterprise to improve the technological maturity of the product platform and modularization, and reduce the factors that lead to a decline in product reliability due to the use of new technologies and new materials during new product development.

5

Design oriented towards supply chain, manufacturing, and service.

The company must specify requirements for product availability, manufacturability, and serviceability for design engineers during product design, and include these requirements in the design task document. These requirements should also be strictly reviewed during the design review process. Reduce changes during the production phase of the product caused by a lack of consideration for supply, manufacturability, and serviceability.

6

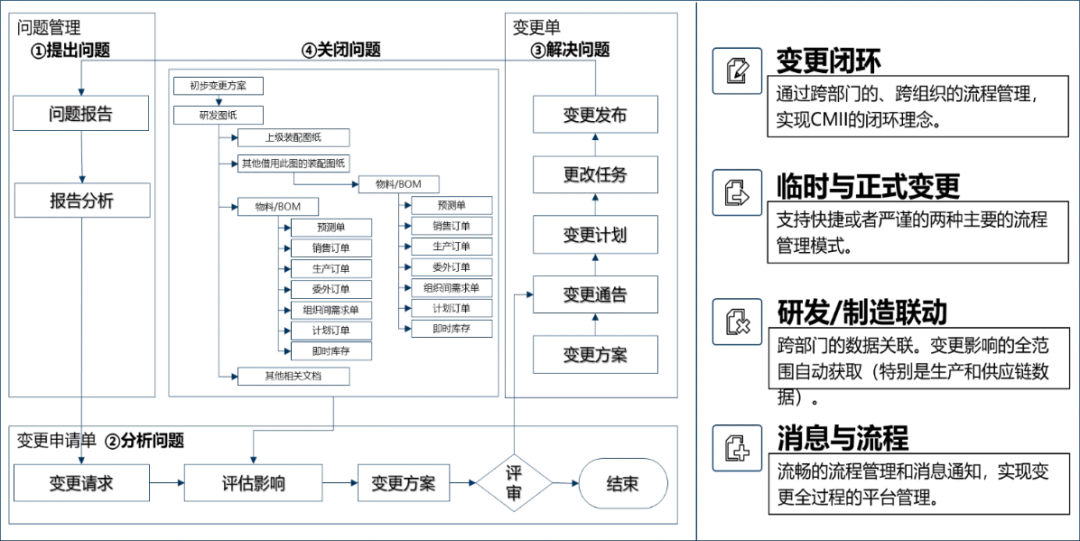

Standardize the design change <Flow> to reduce losses.

Establish a standardized design change process and create different process templates for various scenarios. Once a design change occurs, the first step is to analyze the <x1>Impact Scope</x1> of the change, including which technical documents are affected, which related products, materials, and BOM are involved, as well as the inventory and <x2>In-Transit</x2> and <x3>WIP</x3> status of the materials, in order to develop a reasonable change plan and minimize losses caused by the change.

By establishing a <x1>Management System</x1> for research and development, the quality of product development can be improved, effectively reducing the <x2>Number of</x2> design changes that occur, and compressing design changes as much as possible during the research and development phase, thereby minimizing the impact caused by design changes.

Improving the maturity of research and development management is a challenging process, even a process of moving forward in the dark. We can see the improvement in R&D management levels with joy through the reduction of design change frequency.