AI + operations, becoming an expert in intelligent enterprise health operations management for the manufacturing industry

Insights into AI Application Trends in Manufacturing

In 2025, the global launch of the Deepseek LLM created a huge wave, with many domestic software manufacturers connecting to Deepseek. With its lower model training costs, stronger inference capabilities, more user-friendly open-source model, and benchmark-level understanding of Chinese, Deepseek has ushered in the era of AI popularization, helping Chinese enterprises and the public to be eligible for intelligent achievements.

Focusing on Manufacturing, AI-driven manufacturing operations are gradually deepening, applying advanced AI technologies and intelligent innovations to product delivery, manufacturing operations, and model innovation in manufacturing enterprises. By fully exploring and utilizing core business data from within the enterprise and the industry, it improves production efficiency, enhances product quality, accelerates product innovation, reduces operational costs, and supports efficient operations and scientific decision-making for enterprises, thereby achieving cost reduction, efficiency enhancement, and quality improvement, ultimately enhancing the competitiveness of enterprises.

The “2024 Industry 4.0 Barometer” jointly published by MHP Consulting and Munich University shows that Chinese companies are in a leading position in the application of industrial artificial intelligence. This study surveyed 856 representatives from industrial enterprises in China, the United States, the DACH region (Germany, Austria, Switzerland), and the United Kingdom. The survey results show that among representatives of industrial enterprises in China (248 people), 94% of the companies have already applied artificial intelligence solutions in their manufacturing processes. This percentage is significantly higher than that of industrial enterprises in the United States (46%), the United Kingdom (29%), and the Germany-Austria-Switzerland (DACH) region (20%).

Survey on the Application of Artificial Intelligence in Industrial Enterprises

Source: MHP & Munich University “2024 Industry 4.0 Barometer”

Insights into AI in Manufacturing Business Scenarios

In June 2024, the National Development and Reform Commission, the Ministry of Industry and Information Technology, and three other departments issued the “National Guide for the Construction of a Comprehensive Standardization System for the Artificial Intelligence Industry (2024 Edition),” which emphasizes “AI empowering new industrialization” at the application level. On April 26, 2025, the Ministry of Industry and Information Technology published the “Reference Guidelines for Typical Scenarios of Intelligent Manufacturing (2025 Edition),” which, in accordance with the task requirements of the “14th Five-Year Plan” for the development of intelligent manufacturing, indicates: Decoupling factory operations across the entire product lifecycle, the entire production process, and all links in the supply chain, through the deep integration of new-generation information technology and manufacturing technology, deploying smart manufacturing equipment, industrial software, and intelligent systems, to reconstruct business processes in a digital, networked, and intelligent manner, forming standardized and scalable typical scenarios of smart manufacturing, and further integrating them to constitute a smart factory.

Based on years of exploration and practice in intelligent manufacturing, combined with the trends of technological innovation and integrated application development, 40 typical scenarios of intelligent manufacturing across 8 stages have been distilled. Compared to previous versions, the 2025 guidelines optimize the layout of key stages, create typical scenarios such as digital infrastructure construction, manufacturing engineering optimization, and intelligent business decision-making, highlighting the integrated application of new artificial intelligence technologies in these typical scenarios, and strengthening the guidance for enterprises’ intelligent upgrades.

Examples of Kingdee AI in WIP business scenarios in the manufacturing industry

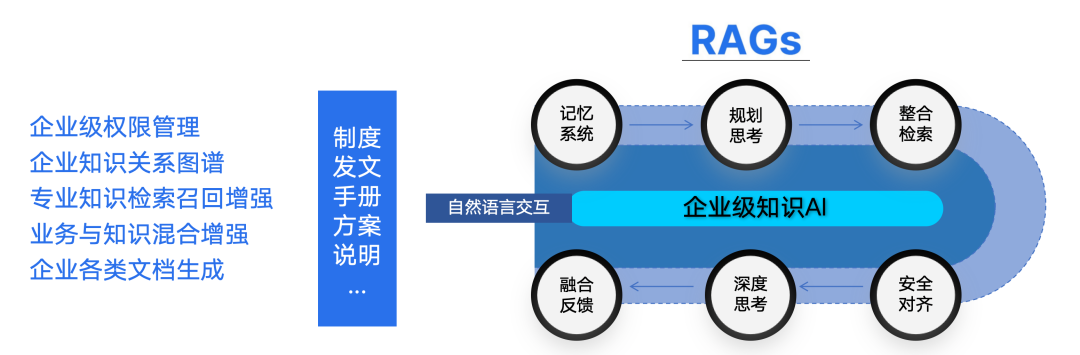

Kingdee is seizing the trend and proposed its fourth transformation—AI transformation—at the beginning of 2025, clearly defining the “AI First Strategy” and publishing the new generation of Kingdee Cloud enterprise-level AI platform. Kingdee has fully integrated DeepSeek into all of its SaaS applications and the Kingdee Cloud Cosmic platform, providing enterprises with a new digital intelligence solution based on native cloud and AI native technologies, as well as a more efficient, secure, and cost-effective enterprise-level AI platform. Delivering high-productivity suites and engineering capabilities for manufacturing applications, promoting the integration of intelligent technology and innovation in high-end manufacturing.

Through the enterprise-level AI platform, based on the concept of “AI + Management,” we create AI + full-scenario services for manufacturing companies, deeply integrating AI technology with manufacturing operations, building a data-driven and intelligent operation smart manufacturing enterprise, and assisting the manufacturing industry in accelerating its digital transformation and upgrade.

In terms of marketing operations

For contracts and orders, delivery date assessment and intelligent review are core links in enterprise supply chain management and contract execution, directly related to customer satisfaction, cost control, and risk avoidance. Through multi-dimensional data modeling, demand priority assessment models, dynamic risk assessment modeling, constraint modeling, and other methods for dynamic simulation and decision recommendations, intelligent evaluation and review of delivery dates can be conducted, production cycles can be reasonably planned, full-process tracking management can be implemented, thereby achieving reasonable responses to contract and order delivery dates, improving order on-time delivery, enhancing customer satisfaction, and shortening review times.

At the supply chain operations level

Kingdee Cloud provides an intelligent collaboration platform that covers all scenarios of enterprise digital procurement. Through convenient supply chain collaboration, it integrates internal and external resources of the enterprise to achieve process automation and transparent, sustainable procurement. This multi-dimensional approach reduces purchase business costs, enhances supply resilience, and prevents supply chain risks. Through the collaboration of sourcing – orders – contracts – logistics – reconciliation – delivery at each stage, based on AI algorithm models, we provide an intelligent procurement platform for the entire industry, covering all categories and scenarios, offering various customizable sourcing methods.

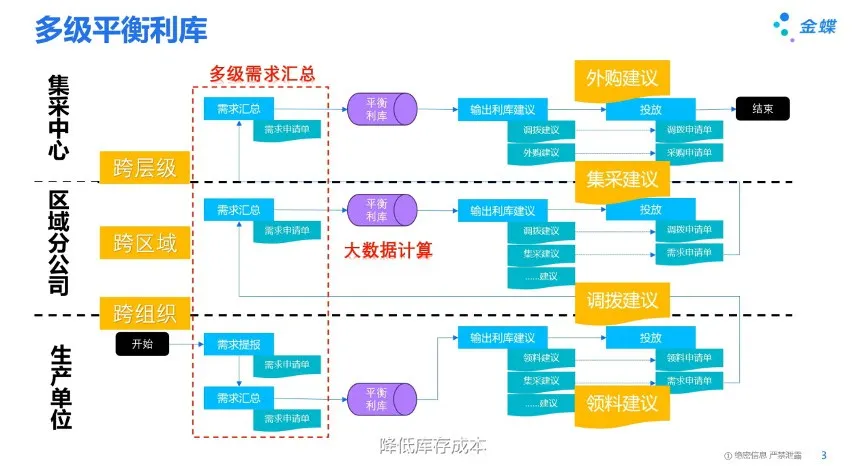

For large or super-large group enterprises, comprehensively plan the business flow, logistics, cash flow, and information flow in the supply chain based on the group’s supply chain plan, integrating the demand and resource information of the upstream and downstream of the supply chain to create the most ideal production efficiency, the most reasonable inventory, and the most accurate timing. Kingdee Cloud Starry Sky evaluates the strategic balance point between inventory planning and demand planning in the supply chain through a balanced inventory model and balanced inventory calculations that span multiple organizations and upstream and downstream operations. This is done while minimizing Inventory Cost to determine the purchase volume, thereby comprehensively enhancing the economic benefits of intensive operations for large group manufacturing enterprises.

Kingdee Cloud Starry Sky creates a supply chain operation center for manufacturing enterprises based on internal and external data, industry data, and combines data intelligence. As a powerful tool for supply chain metrics and operations, it helps manufacturing enterprises understand the overall operational status of the supply chain in real-time. Internally, it can monitor end-to-end processes, sales, procurement, inventory, and other operations. Externally, it can monitor changes in industry chain partners and the external business environment, helping enterprises quickly identify various <x1>exceptions</x1> and risks encountered in supply chain operations, achieve supply chain visualization, and improve supply chain transparency.

At the manufacturing operations level

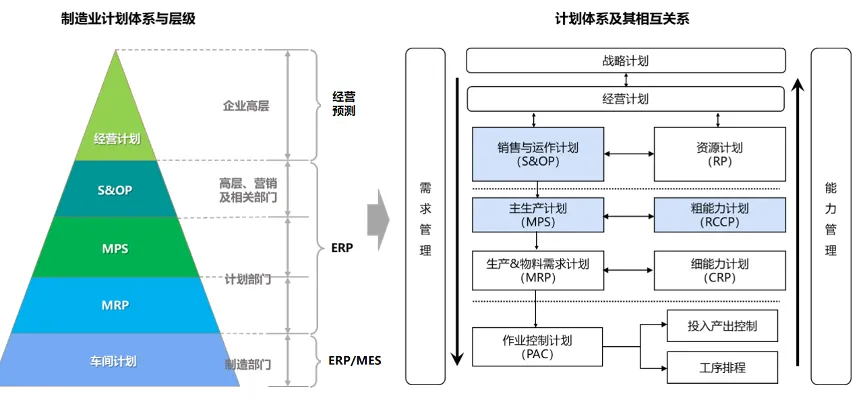

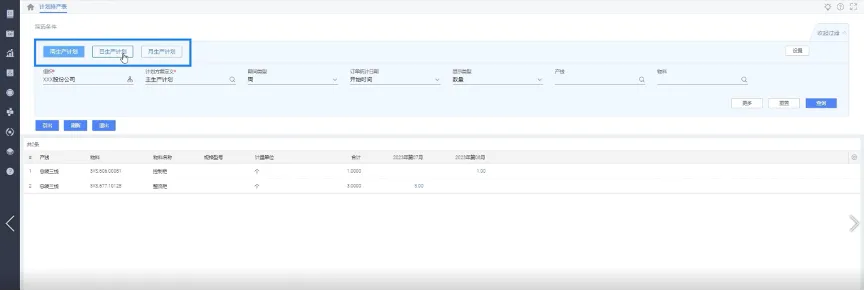

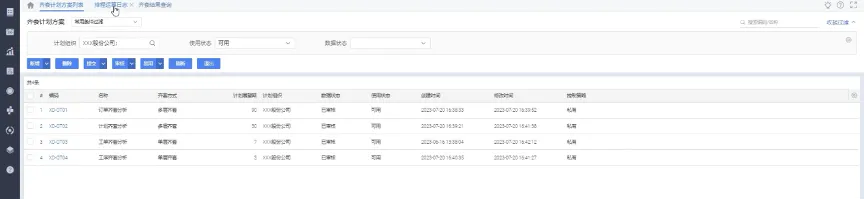

Kingdee Cloud Starry Sky focuses on the manufacturing industry, creating a multi-level lean production planning system based on the concepts of forecast-driven, order-pull, and a combination of push and pull. Through different levels of planning and management, comprehensive planning and control of the production process are achieved, realizing the organization, coordination, and optimization of the production process. The multi-level lean production planning system includes the following levels: Strategy and business plans, sales and operations plans, master production plans, material requirements plans, operations control plans, and real-time monitoring of plans.

The strategic and operational plans mainly carry the long-term business forecasts based on the intelligent budgeting model’s smart calculations, such as annual forecasts and annual plans; the sales and operations plans mainly carry the demand plans formed by intelligent offsetting based on forecasts and demand, as well as the medium- and long-term production and sales coordination plans after intelligent allocation among multiple upstream and downstream factories, such as quarterly plans, monthly plans, etc.; the master production schedule mainly carries the medium- and short-term production plans and resource scheduling that are intelligently scheduled based on the factory’s rough capacity modeling; the material requirements planning mainly carries the short-term production plans and the availability analysis based on the complete set model, which are intelligently calculated based on the detailed capacity modeling of the factory workshop and production line, generating production tasks, outsourcing tasks, and material requirements; the operations control plan mainly carries the detailed process scheduling and control based on production tasks according to specific process routes, combined with intelligently scheduled process capacities; real-time monitoring of plans mainly carries out real-time monitoring and control of plan execution progress and production process exceptions through intelligent data collection.

Kingdee Cloud Starry Sky integrates and connects different levels of plans through hierarchical intelligence, supporting open configurations based on demand forecasting models, multi-factory allocation models, resource constraint models, limited capacity models, priority models, etc. It automatically calculates executable demand intelligence forecasts, annual business plans, quarterly/monthly production plans, and weekly/daily multi-level production plans for manufacturing enterprises. At the same time, based on the complete set model, multi-level demand and plans drive the reserve and procurement of material resources. Additionally, based on production data collection, it achieves transparency and visibility in the production process, along with agile command and scheduling for exceptions. Achieve comprehensive planning and Take Control of the entire production process to guarantee the efficiency, stability, and controllability of the production process; ultimately realize the efficient operations of manufacturing.

Kingdee Cloud Starry Sky is built on the digital operations framework for large and medium-sized manufacturing enterprises, creating a hierarchical and tiered one-stop global operations platform based on the indicator tree and flow tree. Daily business activities are carried out around the <x1>research, production, supply, sales, and service</x1> to achieve close collaboration across various <x2>business domains</x2>, mitigate the <x3>risks</x3> of daily operations, foster a healthy business structure, and maximize <x4>efficiency</x4> and benefits, thereby achieving high-quality development for the enterprise.

The outlook of Kingdee AI in the manufacturing industry

With the continuous advancement of technology, innovation in application models, reduction in application costs, establishment of industry AI standards, and the ongoing enrichment of best practices for intelligent applications in the industry, artificial intelligence technology will play a greater role in promoting the development of the Manufacturing industry towards intelligence and high-end capabilities. Looking ahead, Kingdee remains true to its original intention, continuously deepening its efforts in the manufacturing industry while focusing on industry-specific operations, aiming to create a batch of leading industry large models. Focusing on research and development design, manufacturing, quality inspection, and supply chain management, we aim to unlock the value of industrial data. AI + Manufacturing is being deeply applied on a large scale both domestically and internationally, creating a number of intelligent manufacturing enterprise demonstration factories and excellent scenarios of intelligent manufacturing in the industry, helping to continuously elevate the level of intelligence in China’s Manufacturing.

Source material citation description:

1. Kingdee internal related materials

2. National Guide for the Comprehensive Standardization System Construction of the Artificial Intelligence Industry (2024 Edition)

3. “Reference Guide for Typical Scenarios in Intelligent Manufacturing (2025 Edition)” — Published by the Ministry of Industry and Information Technology

4. “14th Five-Year Plan for Intelligent Manufacturing Development” — published by the Ministry of Industry and Information Technology

5. “Investigation Report on the Current Application of Artificial Intelligence (AI) in Manufacturing” — Source: e-works Research

6. “2024 Industrial 4.0 Barometer” — Source: Munich